Features

SeaMACS IAS Features

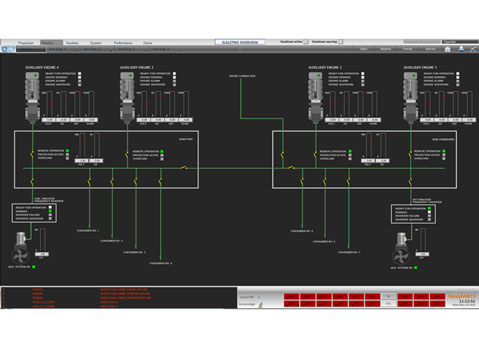

HMI based monitoring systems are useful in many marine applications. HEINZMANN Automation will custom design HMI's and integrate SeaMACS monitoring displays for any application.

- SeaMACS is a scalable system for monitoring and control of any system, or as a full scale integrated control and monitoring system

- Interfaces for trends, reports, alarms and processes

- Customisable, flexible architecture for scalability and redundant system for outmost reliability

- Remote support

- Cloud solution

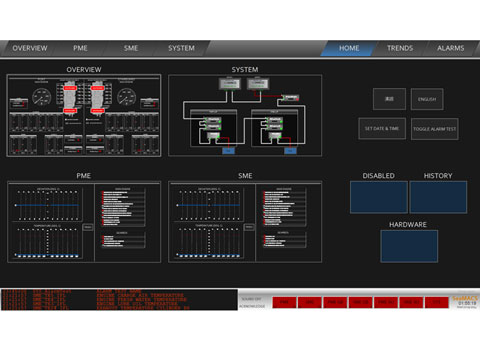

Monitoring

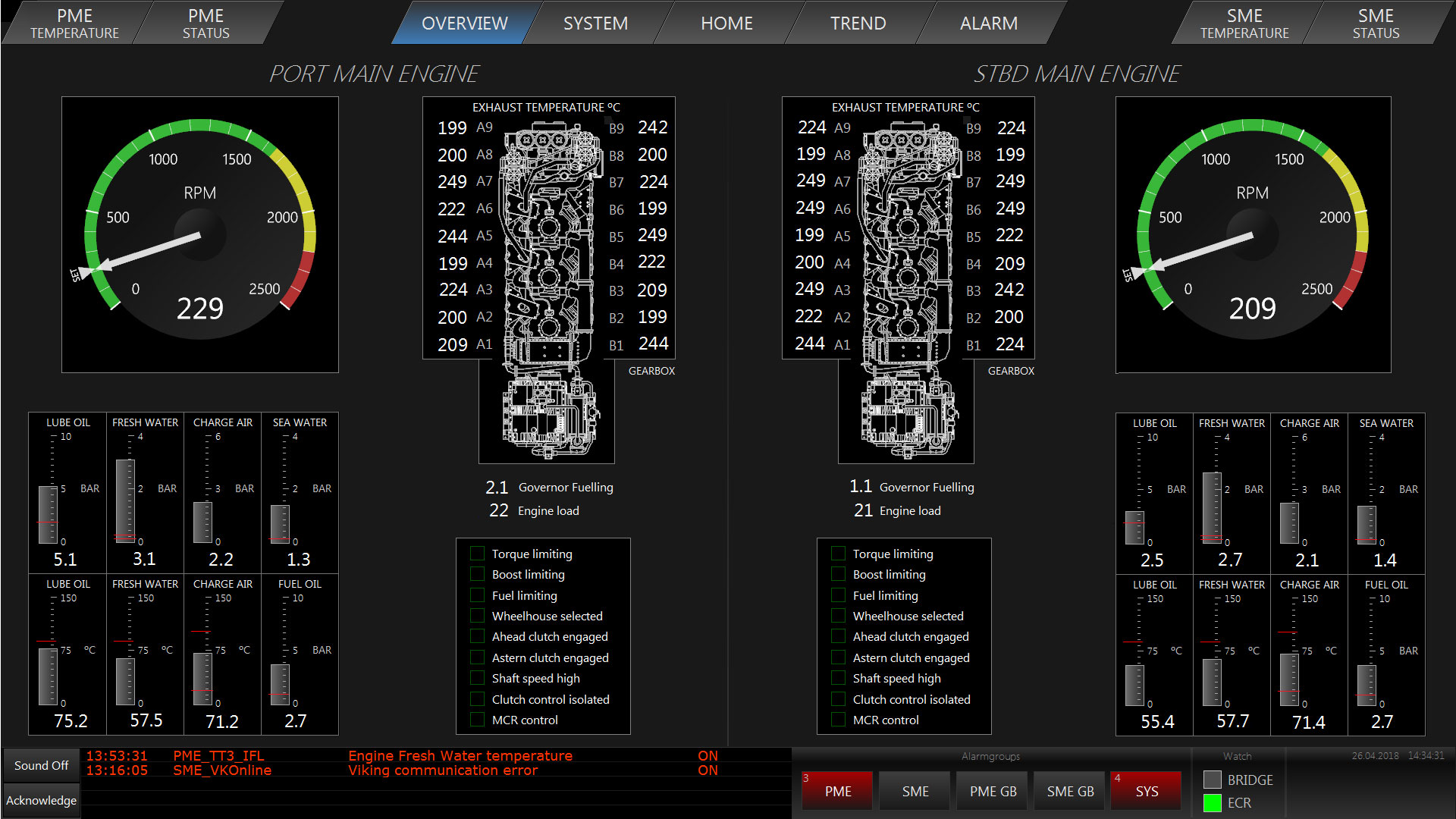

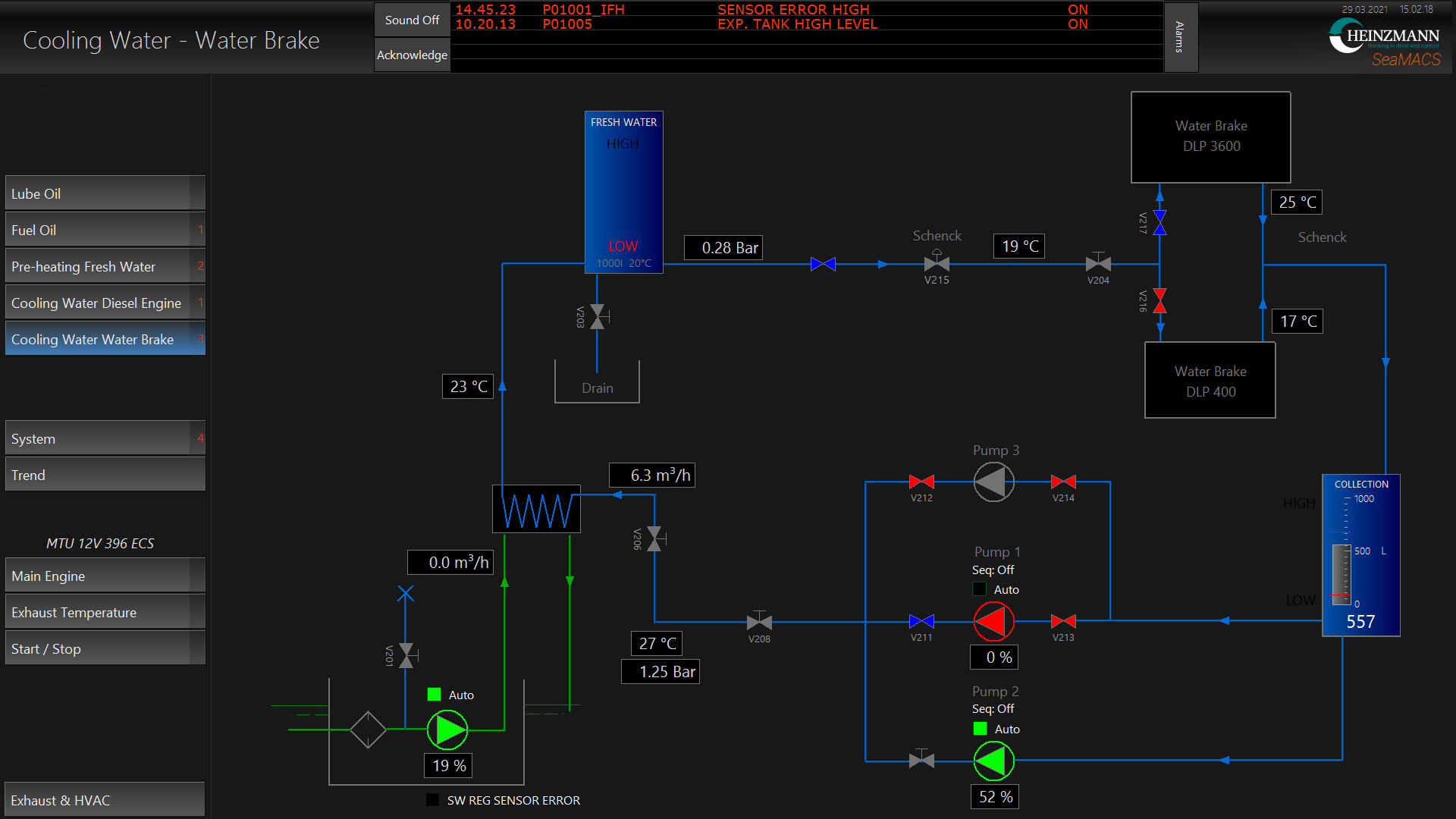

SeaMACS is based on our extensive experience with marine automation systems Our goals is to ensure safe and efficient operation of the vessel.

- All the systems on the ship that connect to the SeaMACS system are monitored and supervised through an intuitive HMI

- The HMI is designed in cooperation with the customer, focusing on the operators needs

- SeaMACS is a scalable system for monitoring and control of any system, or as a full scale integrated control and monitoring system

- Interfaces for trends, reports, alarms and processes

- Customisable, flexible architecture for scalability and redundant system for outmost reliability

- Remote support

- Cloud solution

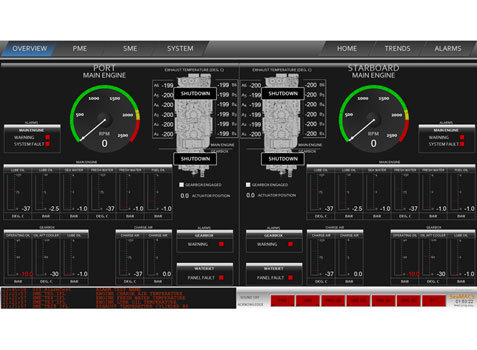

Control

SeaMACS can interface with any system for remote control and monitoring.

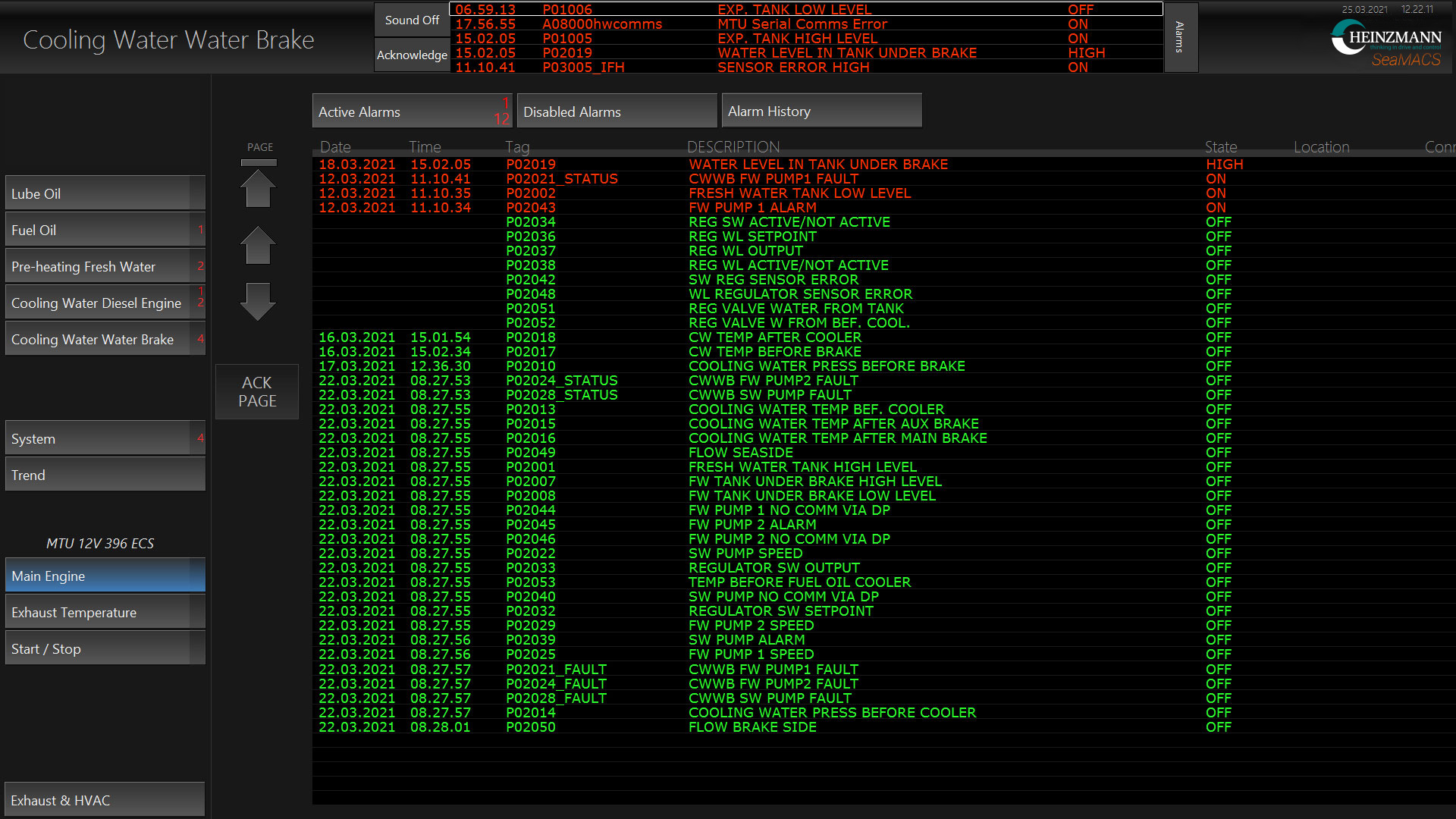

Alarms

SeaMACS includes all alarm functionality required to fulfil class requirements.

- All current active alarms

- A summary of a predefined number of the last active alarms

- An alarm history log that stores all alarm conditions and alarm transitions for a predefined period

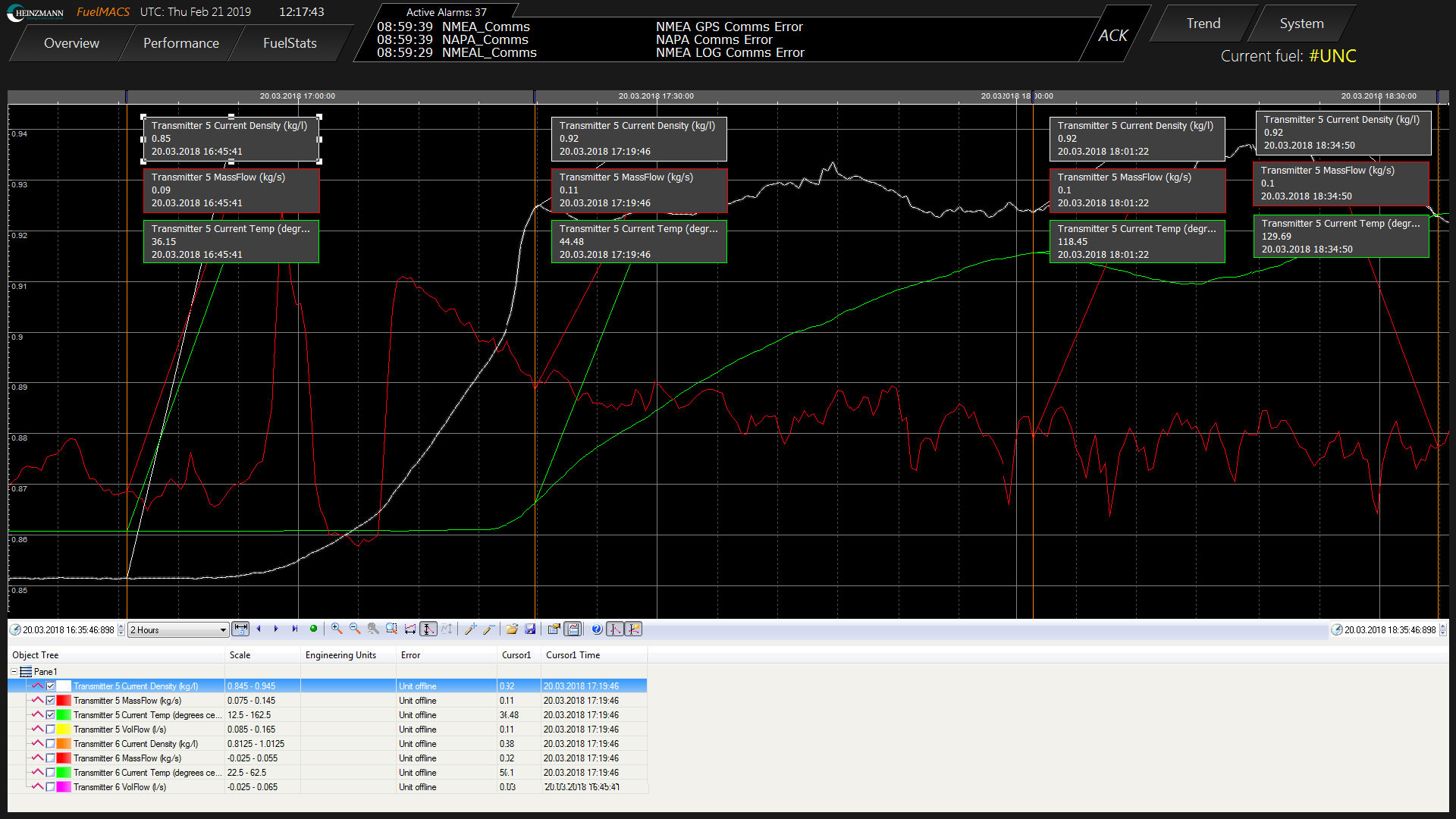

In addition, the system offers a combined trend and alarm view which allows performing analysis of trend and alarms together. That way, the operator can analyse trends and alarms for a given time span in one single window.

Trend

SeaMACS includes an extensive tool for trending of values and equipment statuses.

Trends can be set to collect and monitor data. Depending on the requirements the data can either be collected periodically or when a specific situation occurs.

- Trends can be set up to store a given set of tags, or all tags on the ship can be trended and kept for later analysis

- Historical data gives the operator flexibility and the capability to review situations and incidents

- Trending view can be combined with alarms, which allows performing analysis of trend and alarms together - that way the operator can analyse trends and alarms for a given time span in one single window

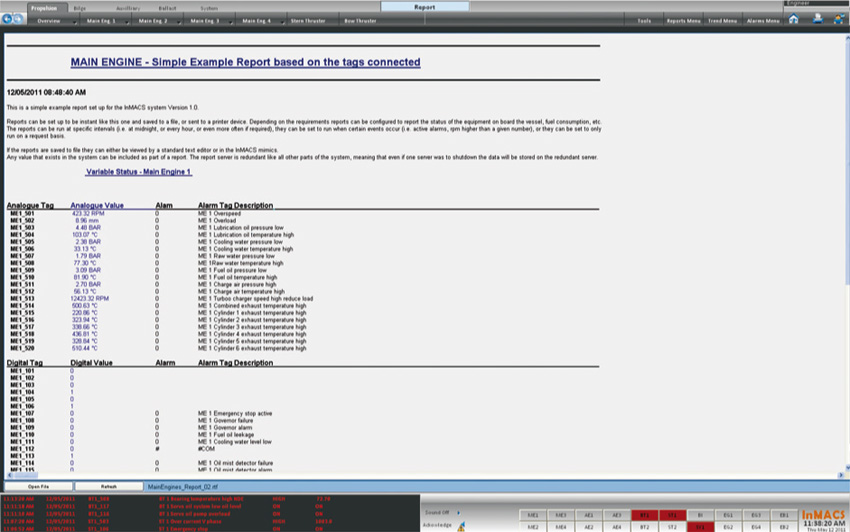

Reports

SeaMACS includes report functionality, that can be created based on the status of the system or when special conditions occur in the system.

SeaMACS Integrated Automation Systems

One of the main benefits of the SeaMACS is the system scalability. It can be delivered both as a stand-alone alarm and monitoring system, as well as a fully Integrated Automation System (IAS) where the user will monitor as well as control.

SeaMACS IAS Benefits

Reliability through redundant architecture

- Redundant architecture allows for safe operation and minimum downtime of the system

- Providing optimum reliability

- Avoids costs and damage to equipment induced by downtime

- Redundancy both at top level and lower level as standard

Scalability of network architecture

- Ethernet-based system allows for efficient handling of large amounts of data

- Meets future requirements for SCADA networks and is transparent and scalable

- Can easily be expanded or modified for future upgrades or add-ons without having to modify existing system hardware or software

Intuitivity and connectivity of user-interfaces

- The user-interface helps the operator easily navigate within the IAS

- Over 150 communication drivers included in the software

- Allowing for interfacing between over 300 different types of I/O devices, PLCs and other systems